Clinker size and cement grinding

Clinker size and cement grinding

Clinker size is important for the optimization of cement grinding, and is also an indicator of cement quality. Having a high percentage of coarse clinker can be difficult to grind. However, having a high percentage of fine clinker can also be hard to grind and have a negative impact on cement performance. Large clinker particles are usually an indication of a possible issue with the kiln cooler crusher, while high levels of fines are usually an indication of unsatisfactory kiln operation. Under-burning or over-burning typically results in too much fine clinker and can often be associated with lower quality.

It is usual to target a mid-range for both free lime (1-2%) and granulometry (less than 25% passing 1mm and less than 25% above 25mm).

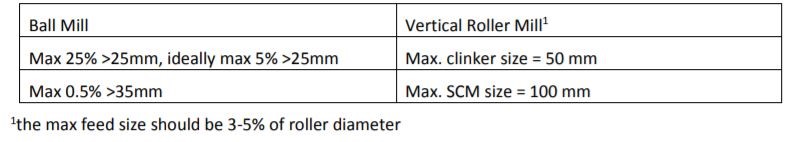

For most mill systems, manufacturers recommend the following raw material size:

Fine clinker is more of an issue in vertical roller mills, since it can quickly slip under the rollers, leading to vibration and instability. As a general rule, there should be less than 25% of clinker that is below 1mm in size.

Coarse clinker is more of an issue for ball mills. Some cement groups use a formula, such as Bond’s, to calculate the maximum ball size required in a ball mill, based on the average size of the clinker feed.

However, one drawback with this approach is that in some cases the formula will result in the prediction that 100mm balls be used to deal with large clinker particles. The trouble with this is that most mill and liner suppliers do not recommend the use of 100mm balls, as they increase the risk of liner plate damage. An assessment of clinker “hardness” (for example by simply dropping 60-90mm balls from 1m height onto the larger clinker pieces) and the percentage >25mm are useful guides to 1st chamber ball charge selection and specifically the percentage at 90mm. For ball mills, it is more efficient to reduce the size of large particles prior to the mill, using physical means such as a hammer crusher, pre-grinder, or a roll press.

Fine clinker is less of an issue in a ball mill, since the material simply passes through to the second chamber for fine grinding, although this can reduce the impact of the 1st chamber crushing action somewhat. However, higher clinker fines content can often lead to harder grindability and so the target for less than 25% of clinker that is below 1mm in size is also appropriate for ball mills.

Learn more about the latest cement production additives.

Tags

- Cement Grinding

- Cement production

- Consultant

- OPTEVA™

- Producer

- Sustainability

- TAVERO™